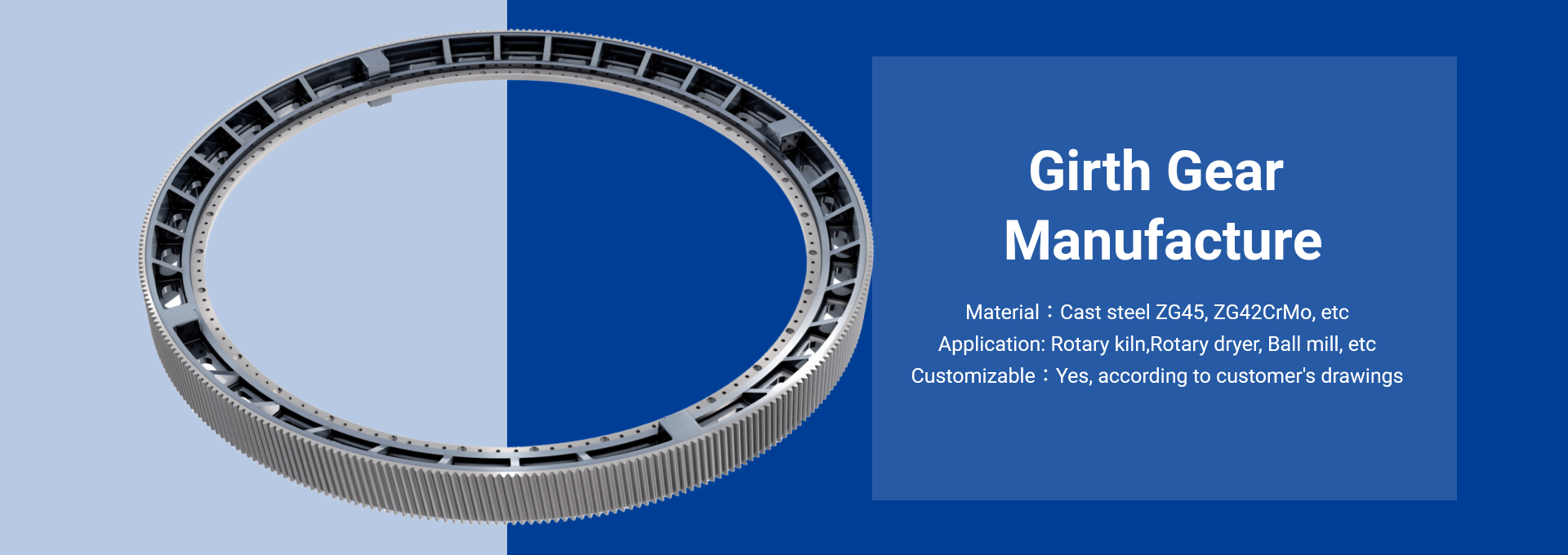

Girth gears are used in a number of the world’s critical industries, including mining, cement andminerals. Usually fitted to the outside of horizontal mill, ball mill and rotary kiln.

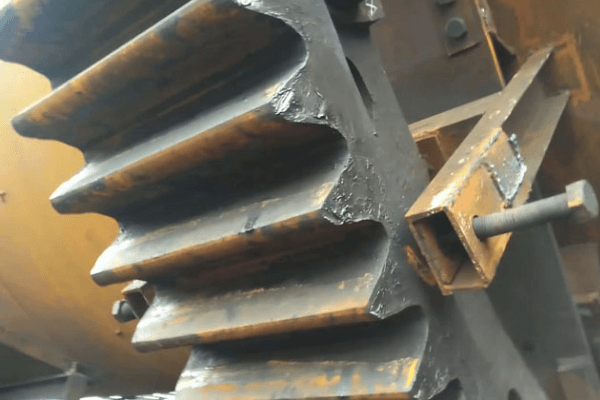

Girth gears provide the system’s primary rotational drive and as such need to be robust, efficient and built to last. Girth gears are used in a number of mining, cement and minerals processing applications, including copper, gold, silver, platinum and iron ore production where operational downtime is not an option.

Tenfaye Girth Gear

Green Casting, Wining with Quality

Ball mill

SAG (semi autogenous grinding) mills

Mining ball mill

Cement industry

Kilns

Dryers

Coolers

Use CAE software to simulate the filling and solidification process of castings, Professional heat treatment process to improve the hardness, wear resistance and impact resistance of the girth gear. UT, MT, PT system to ensure quality.

Girth gears can be supplied individually, or as part of a fully optimised MDX mill drive package which includes:

Mill drive gearbox Girth gear

Pinions Barring drive

Auxiliary equipment including couplings, brakes, pedestal

bearings and clutches

Design

Simulation

& analysis

Casting

Parts

processed

Finishing

machining

Packaging

& delivery